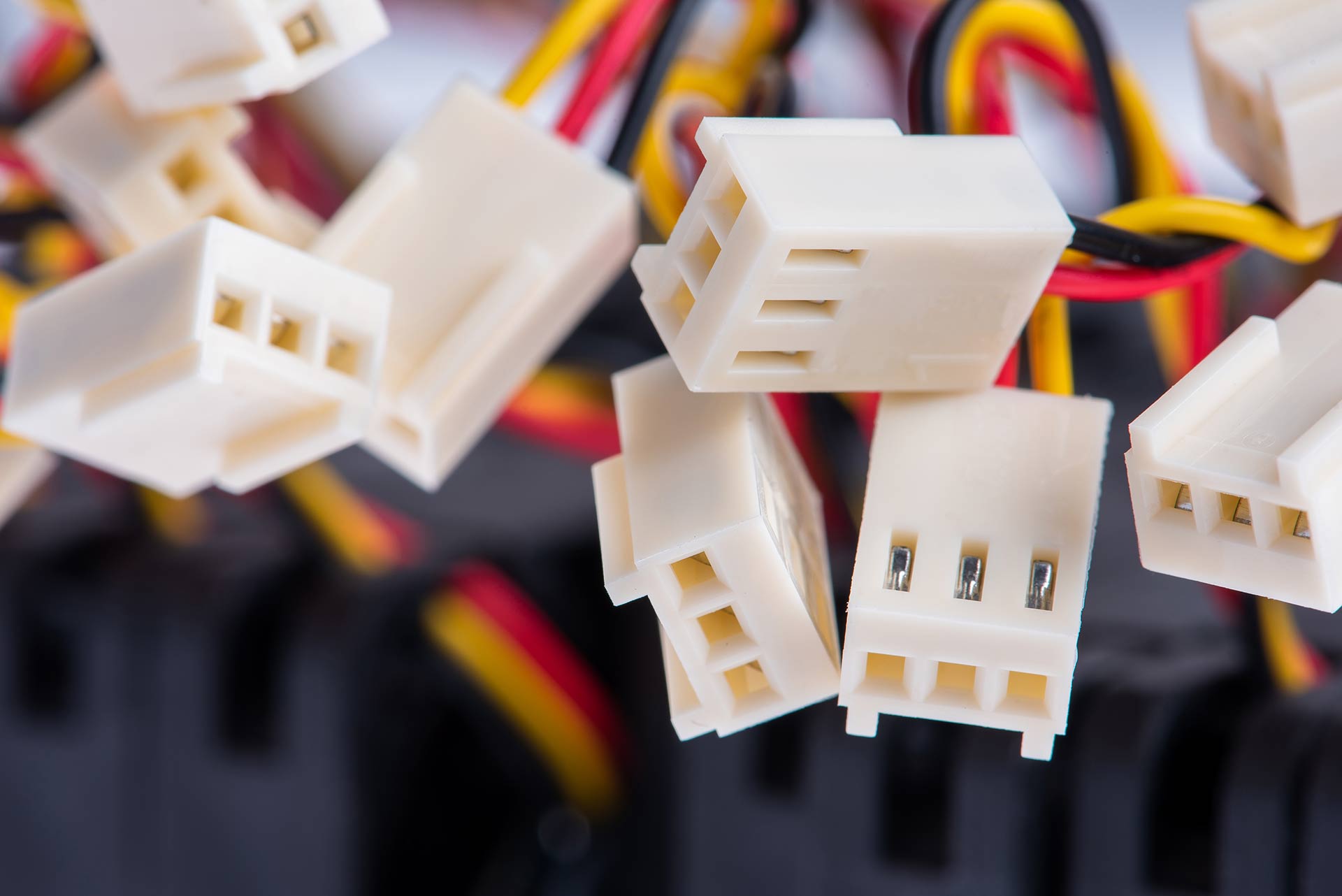

DSB Series Edge Connectors

Specialized connectors designed for high-reliability applications where printed circuit board (PCB) edge connections are required

Here’s a step-by-step breakdown of how we company typically produce these components:

The DSB Series Edge Connectors are specialized connectors designed for high-reliability applications where printed circuit board (PCB) edge connections are required. These connectors facilitate secure electrical connections by engaging with the PCB edge, making them ideal for applications requiring frequent mating and unmating.

- Key Features of DSB Series Edge Connectors

- Edge Card Interface: Designed to mate with the edge of a PCB, eliminating the need for additional wiring.

- High Durability: Supports multiple mating cycles without compromising electrical integrity.

- Metal Contacts: Typically made from copper alloy with tin, silver, or gold plating for enhanced conductivity and corrosion resistance.

- Plastic Housing: Constructed from heat-resistant thermoplastics such as PBT or LCP (liquid crystal polymer) to withstand high temperatures and harsh conditions.

- Various Pin Configurations: Available in multiple pin counts to support different applications.

- Locking Mechanisms: Some variants include retention clips or latching features to secure the connection.

- High Current Handling: Capable of handling moderate to high currents depending on the application.

- Manufacturing Process

- a) Contact Stamping & Plating

- Copper alloy sheets are stamped to form precise connector contacts.

- The contacts are plated (tin, gold, or silver) to improve conductivity and prevent oxidation.

- b) Injection Molding (Housing)

- The connector housing is injection-molded from durable thermoplastics.

- Tolerances are tightly controlled to ensure a secure PCB fit.

- c) Assembly

- Stamped contacts are inserted into the housing using automated assembly equipment.

- Additional locking or retention features may be incorporated.

- d) Quality Testing

- Electrical Testing: Verifies continuity, resistance, and insulation.

- Mechanical Testing: Checks mating/unmating forces, retention strength, and durability.

- Environmental Testing: Evaluates performance under heat, vibration, and humidity conditions.

- Applications of DSB Series Edge Connectors

- Automotive Electronics (e.g., infotainment systems, control modules)

- Power Distribution Systems

- Industrial Equipment

- Data & Communication Devices

- Consumer Electronics

Our DSB Series Edge Connectors

DIN plugs

DIN plugs are standardized electrical connectors originally developed by the Deutsches Institut für Normung (DIN), the German standards organization

ISO connectors for 2.8mm - 0.110

Our connectors are designed for reliable power and signal connections, ensuring secure and efficient interconnectivity in various systems

Pitch 5.0 mm. connectors - 0.197

connectors are power and signal connectors designed for wire-to-wire and wire-to-board applications