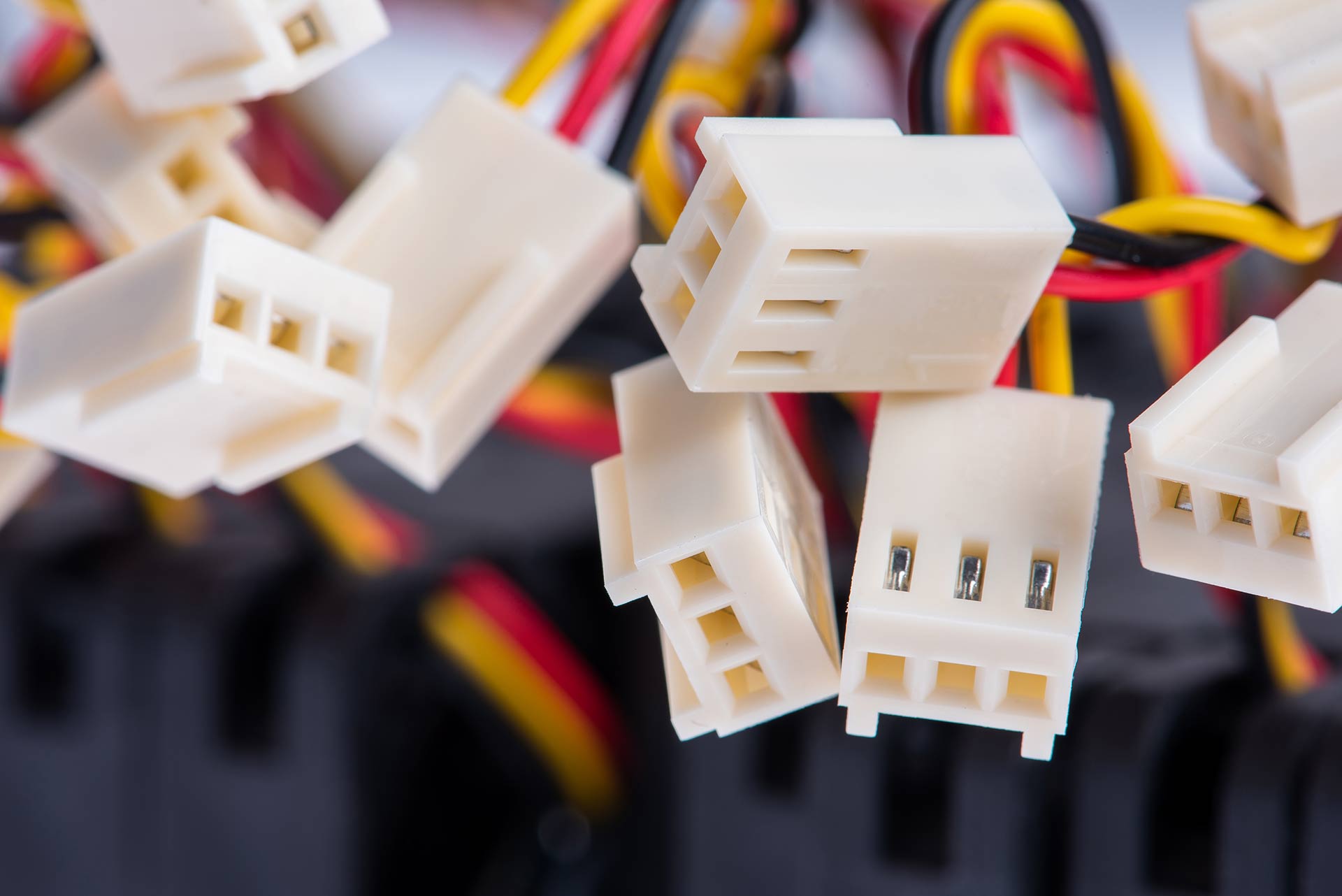

Pitch 3.96 mm [.156] connectors 396 series

A family of 3.96 mm (.156 inch) pitch connectors designed for power and signal applications that require reliable, high-current connections.

Here’s a step-by-step breakdown of how we company typically produce these components:

The 396 Series connectors are a family of 3.96 mm (.156 inch) pitch connectors designed for power and signal applications that require reliable, high-current connections. These connectors are commonly used in automotive, industrial, and consumer electronics applications where space efficiency and secure connections are essential.

- Key Features of 396 Series Connectors

- 3.96 mm (.156”) Pitch: Provides a balance between compact size and power-handling capability.

- High Current Capacity: Typically rated for up to 7A per circuit, depending on wire size and terminal type.

- Wire-to-Wire & Wire-to-Board Options: Supports both direct wiring and PCB mounting.

- Multiple Pin Configurations: Available in 2 to 24 positions, in both single- and dual-row layouts.

- Locking Mechanisms:

- Friction locks for basic retention.

- Latching features for enhanced security in high-vibration environments.

- Polarized Design: Prevents incorrect mating and misalignment.

- Durable Materials:

- Housing: Constructed from high-temperature thermoplastics (e.g., PBT or Nylon 66).

- Contacts: Made from copper alloy, with tin, gold, or silver plating for improved conductivity and corrosion resistance.

- IDC (Insulation Displacement) & Crimp Termination Options: Allows for fast and secure wire connections.

- Surface Mount & Through-Hole PCB Options: Available in both THT (through-hole) and SMD (surface-mount)configurations.

- Manufacturing Process

- a) Contact Stamping & Plating

- Stamped terminals are made from phosphor bronze or brass, ensuring mechanical strength.

- Plating is applied (tin, gold, or silver) to improve electrical conductivity and corrosion resistance.

- b) Injection Molding (Connector Housing)

- Thermoplastic materials are injection-molded into precise housing shapes with built-in keying features.

- The housings are designed to withstand high temperatures and mechanical stress.

- c) Terminal Assembly & Wire Termination

- Crimp-type connectors: Terminals are crimped onto wires and inserted into the housing until they lock securely.

- IDC (Insulation Displacement) versions: Wires are pushed into insulation displacement slots, eliminating the need for stripping.

- Board-mount versions: Terminals are either soldered into through-hole PCB pads or mounted using surface-mount techniques.

- d) Testing & Quality Control

- Electrical Testing: Ensures proper continuity, insulation resistance, and voltage ratings.

- Mechanical Testing: Verifies retention force, mating/unmating cycles, and durability.

- Environmental Testing: Simulates vibration, thermal cycling, humidity exposure, and chemical resistance.

- Applications of 396 Series Connectors

- Automotive Electronics (e.g., power distribution modules, lighting systems, engine control units)

- Industrial Equipment (e.g., motor controllers, automation systems, power supplies)

- Home Appliances (e.g., HVAC systems, washing machines, refrigerators)

- LED & Lighting Systems

- Power & Signal Connectivity in Telecommunications & Networking Devices

Our Pitch 3.96 mm [.156] connectors 396 series

DIN plugs

DIN plugs are standardized electrical connectors originally developed by the Deutsches Institut für Normung (DIN), the German standards organization

ISO connectors for 2.8mm - 0.110

Our connectors are designed for reliable power and signal connections, ensuring secure and efficient interconnectivity in various systems

Pitch 5.0 mm. connectors - 0.197

connectors are power and signal connectors designed for wire-to-wire and wire-to-board applications