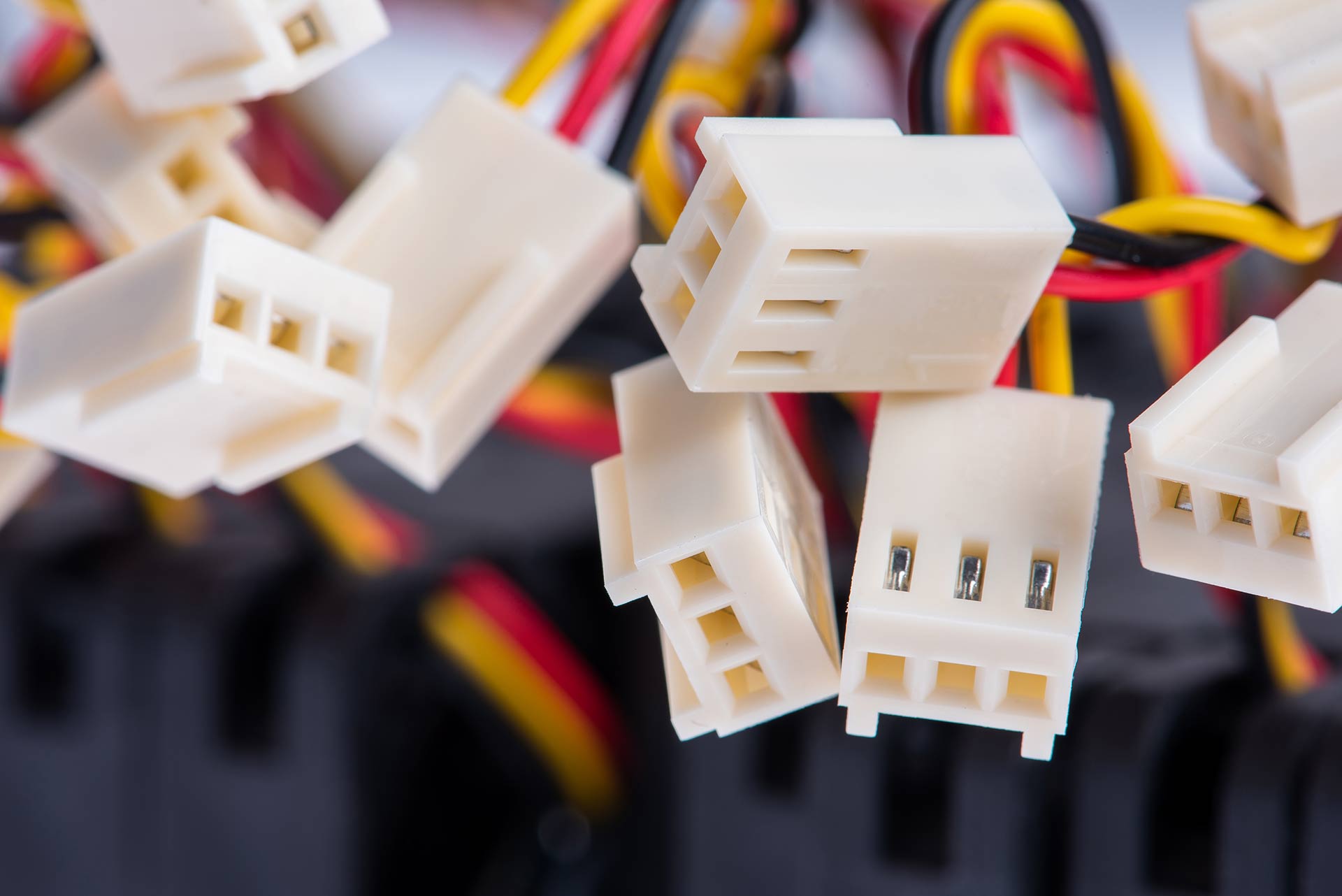

QUICK CONNECT INSULATION HOUSING

Designed to provide a protective and insulated covering for quick-connect terminals, ensuring electrical safety, secure connections, and resistance to environmental factors.

Here’s a step-by-step breakdown of how we company typically produce these components:

Quick Connect Insulation Housing is designed to provide a protective and insulated covering for quick-connect terminals, ensuring electrical safety, secure connections, and resistance to environmental factors. These housings are widely used in automotive, industrial, and consumer electronics applications to prevent accidental short circuits and enhance mechanical stability.

- Key Features of Quick Connect Insulation Housing

- Compatibility: Designed to fit standard quick-connect (faston/tab) terminals, typically 2.8 mm, 4.8 mm, 6.3 mm, and 9.5 mm sizes.

- Electrical Insulation: Prevents short circuits and accidental contact, ensuring safety in high-voltage applications.

- Durable Material Construction:

- Thermoplastic materials (e.g., Nylon, PVC, or Polycarbonate) for heat and flame resistance.

- Some versions use silicone or rubber for flexibility in extreme environments.

- Flame Retardant Options: Available in UL94-V0 rated materials for enhanced fire resistance.

- Snap-On or Slide-In Design:

- Allows for quick and secure assembly over quick-connect terminals.

- Some versions have locking tabs for additional retention.

- Temperature & Chemical Resistance:

- Can withstand high operating temperatures (typically -40°C to 105°C or higher).

- Resistant to oils, solvents, and moisture in harsh environments.

- Clear or Colored Variants: Available in transparent or color-coded versions for easy identification and inspection.

- Manufacturing Process

- a) Material Selection & Preparation

- High-performance thermoplastic granules (e.g., PBT, Nylon, PVC, or Polycarbonate) are selected for their electrical insulation and mechanical strength.

- b) Injection Molding

- The selected thermoplastic material is melted and injected into precision molds to form the insulation housing.

- Molded housings are cooled and ejected for further processing.

- c) Quality Control & Testing

- Dielectric Strength Testing: Ensures insulation effectiveness under high voltage conditions.

- Flammability Testing: Some versions undergo UL94 flammability testing for safety compliance.

- Mechanical Testing: Evaluates retention force, impact resistance, and durability.

- Environmental Testing: Assesses performance under temperature fluctuations, humidity, and exposure to chemicals.

- Applications of Quick Connect Insulation Housing

- Automotive Wiring Systems (e.g., power distribution, ignition systems, sensors)

- Industrial Equipment & Machinery (e.g., motor controllers, HVAC systems, power tools)

- Consumer Electronics & Appliances (e.g., household appliances, lighting fixtures, circuit protection)

- Renewable Energy Systems (e.g., solar inverters, battery connections)

- Telecommunication & Power Distribution Panels

Our QUICK CONNECT INSULATION HOUSING

DIN plugs

DIN plugs are standardized electrical connectors originally developed by the Deutsches Institut für Normung (DIN), the German standards organization

ISO connectors for 2.8mm - 0.110

Our connectors are designed for reliable power and signal connections, ensuring secure and efficient interconnectivity in various systems

Pitch 5.0 mm. connectors - 0.197

connectors are power and signal connectors designed for wire-to-wire and wire-to-board applications