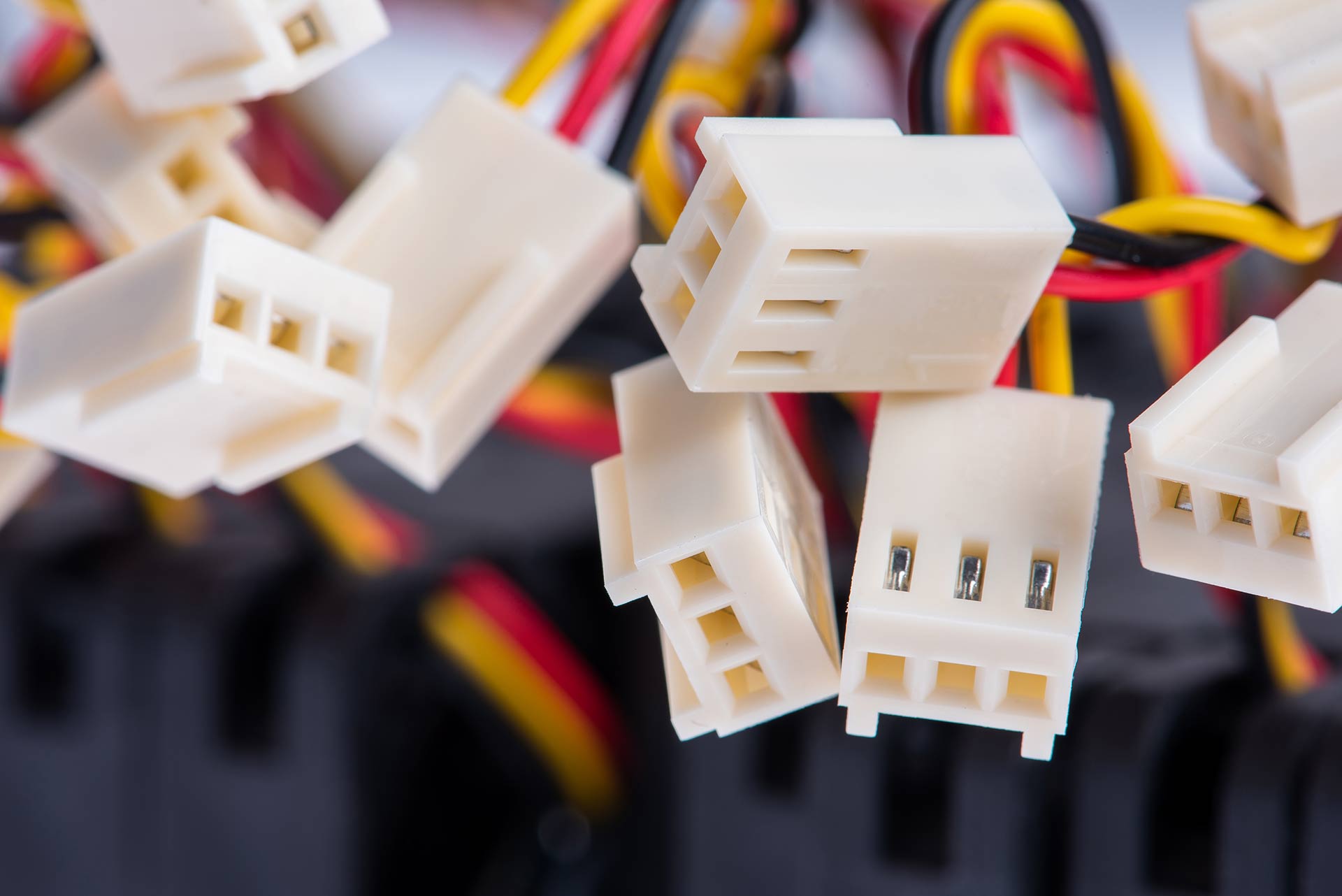

RAST 5 Series crimping

A standardized connector system with a 5.0 mm pitch, widely used in appliance, automotive, and industrial applications.

Here’s a step-by-step breakdown of how we company typically produce these components:

RAST 5 (Raster Anschluss Steck Technik 5 mm) is a standardized connector system with a 5.0 mm pitch, widely used in appliance, automotive, and industrial applications. Crimping in RAST 5 Series refers to the process of securely attaching terminals to wires before they are inserted into the connector housing. This ensures reliable electrical connections with high retention strength and durability.

- Key Features of RAST 5 Crimping

- 5.0 mm Pitch: Designed for power and control connections, offering secure wire-to-board and wire-to-wire interconnects.

- Crimped Terminals:

- Typically made from copper alloys (brass or phosphor bronze) for conductivity and mechanical strength.

- Plated with tin, gold, or silver to enhance corrosion resistance and contact reliability.

- High Current Capacity: Supports currents up to 16A per circuit, depending on wire gauge and terminal type.

- Pre-Crimped Wire Solutions: Available as pre-assembled crimped wires, simplifying production and assembly.

- Locking & Coding Options:

- Keying mechanisms to prevent incorrect connections.

- Secondary locking features for additional retention in high-vibration environments.

- Automation Friendly: Compatible with automated crimping and insertion processes to increase efficiency in mass production.

- RAST 5 Crimping Process

- a) Wire Preparation

- Wires (typically AWG 16-22) are cut to the required length.

- The insulation is precisely stripped to expose the correct length of conductor.

- b) Terminal Crimping

- The terminal is placed onto the exposed wire strands.

- A crimping machine or tool compresses the terminal’s crimping tabs around the wire, creating:

- A gas-tight electrical connection to prevent oxidation.

- A secure mechanical bond to ensure durability.

- The crimped terminal undergoes quality inspection (force measurement, visual checking).

- c) Terminal Insertion into RAST 5 Housing

- The crimped terminal is pushed into the connector housing until it clicks into place.

- Some versions use automated insertion systems for higher efficiency.

- d) Quality Control & Testing

- Pull Force Testing: Ensures the crimped connection withstands required tension.

- Electrical Testing: Measures contact resistance and ensures continuity.

- Environmental Testing: Checks for heat, humidity, and vibration resistance.

- Applications of RAST 5 Series Crimping

- Household Appliances (e.g., dishwashers, washing machines, refrigerators)

- Automotive Electronics (e.g., power distribution, climate control, lighting)

- Industrial Control Systems (e.g., motor controllers, automation modules)

- HVAC Systems (e.g., thermostats, fan controllers)

- Power & Energy Systems (e.g., solar inverters, battery packs)

Our RAST 5 Series Crimping Connectors

DIN plugs

DIN plugs are standardized electrical connectors originally developed by the Deutsches Institut für Normung (DIN), the German standards organization

ISO connectors for 2.8mm - 0.110

Our connectors are designed for reliable power and signal connections, ensuring secure and efficient interconnectivity in various systems

Pitch 5.0 mm. connectors - 0.197

connectors are power and signal connectors designed for wire-to-wire and wire-to-board applications