Connectors for LK terminals

LK terminals are a specific type of automotive terminal designed for high reliability, particularly in power and signal transmission applications.

Here’s a step-by-step breakdown of how we company typically produce these components:

LK terminals are a specific type of automotive terminal designed for high reliability, particularly in power and signal transmission applications. Connectors designed for LK terminals are engineered to provide secure electrical connections, high resistance to environmental factors, and durability in demanding automotive conditions.

- Characteristics of LK Terminal Connectors

- High Retention Force: LK terminals are designed to lock securely into the connector housing, ensuring a firm and vibration-resistant connection.

- Compact Design: Typically used in space-constrained areas, LK terminal connectors have a compact form factor.

- Durable Materials:

- Housings: Made from high-performance thermoplastics (e.g., PBT, PA66) to resist heat, chemicals, and UV exposure.

- Terminals: Composed of copper alloys (brass or phosphor bronze) with tin, silver, or gold plating for improved conductivity and corrosion resistance.

- Sealing Options: Available in both sealed (with silicone gaskets) and unsealed versions, depending on the application.

- Key Manufacturing Processes for LK Terminal Connectors

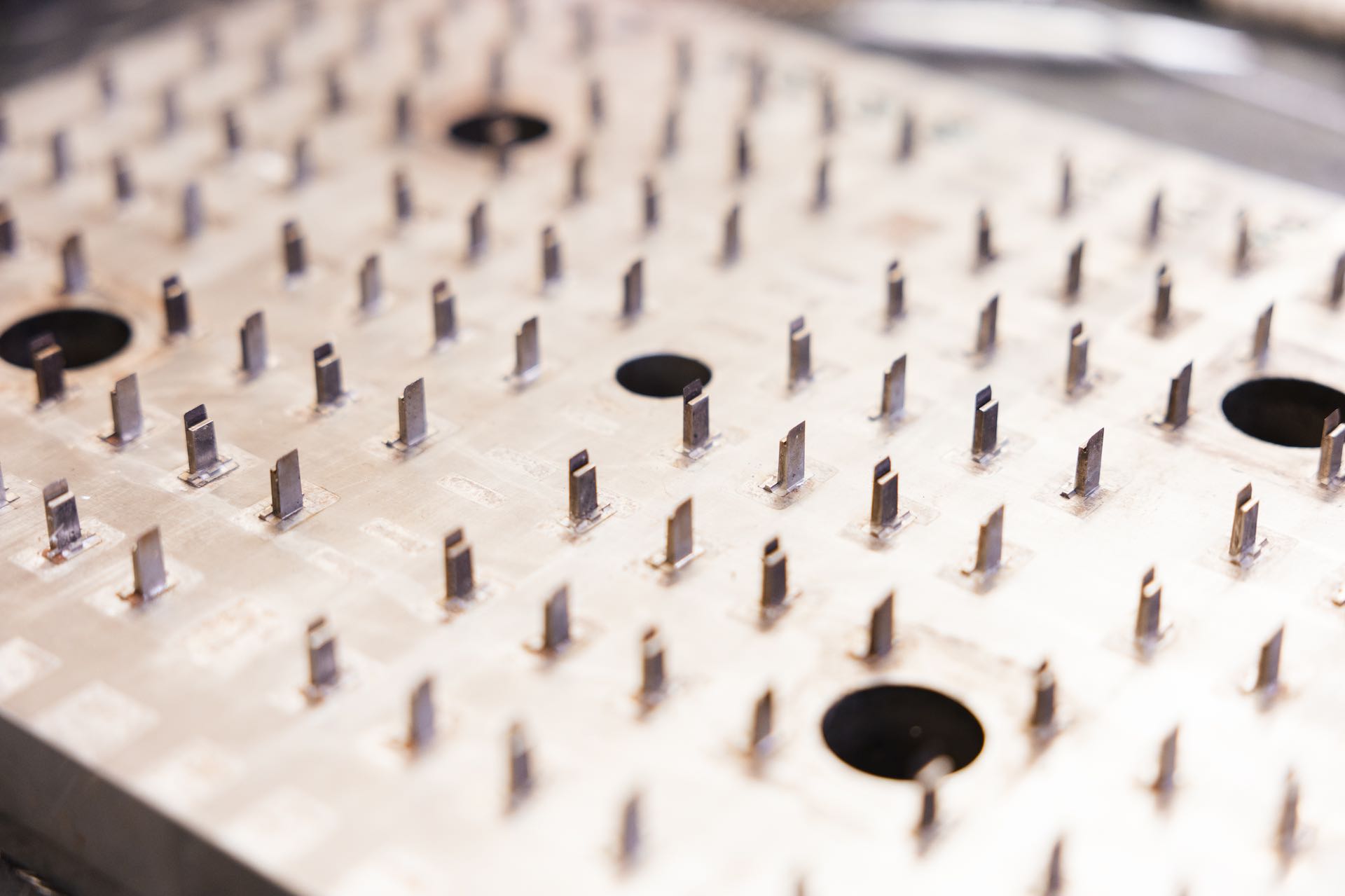

- a) Stamping (Metal Terminals)

- LK terminals are stamped from metal sheets in high-speed progressive die stamping machines.

- Post-stamping processes such as plating (tin, silver, or gold) enhance conductivity and corrosion resistance.

- b) Injection Molding (Connector Housing)

- Plastic granules are melted and injected into precision molds to create the connector housings.

- Sealing components (e.g., rubber gaskets) are added to weatherproof versions.

- c) Terminal Insertion & Assembly

- LK terminals are crimped onto wires using automated crimping machines.

- The crimped terminals are inserted into the connector housing, ensuring a secure mechanical and electrical connection.

- Retention locks and secondary locking mechanisms may be added for additional security.

- d) Testing & Quality Control

- Electrical Testing: Checks for proper conductivity and resistance.

- Mechanical Testing: Ensures retention force, insertion force, and mating cycles are within specifications.

- Environmental Testing: Simulates temperature extremes, humidity, vibration, and chemical exposure.

- Applications of LK Terminal Connectors

- Power Distribution Modules

- ECUs (Engine Control Units)

- Sensor Connections

- Lighting Systems

- Battery & Charging Systems

Our LK Terminal Connectors

For miniature terminals diameter 1.0 mm. - 0.39

Connectors designed for LK terminals are engineered to provide secure electrical connections

For universal terminals diameter 2.12 mm. - 0.84

High resistance to environmental factors, and durability in demanding automotive conditions